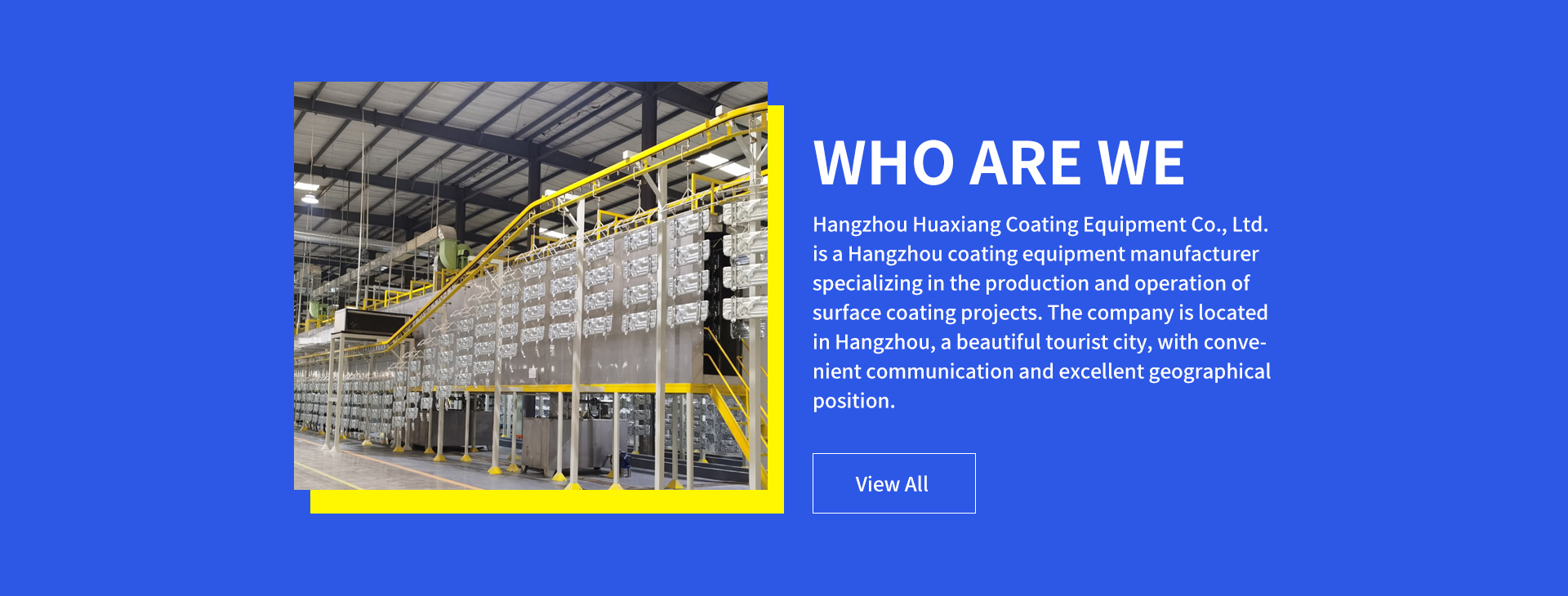

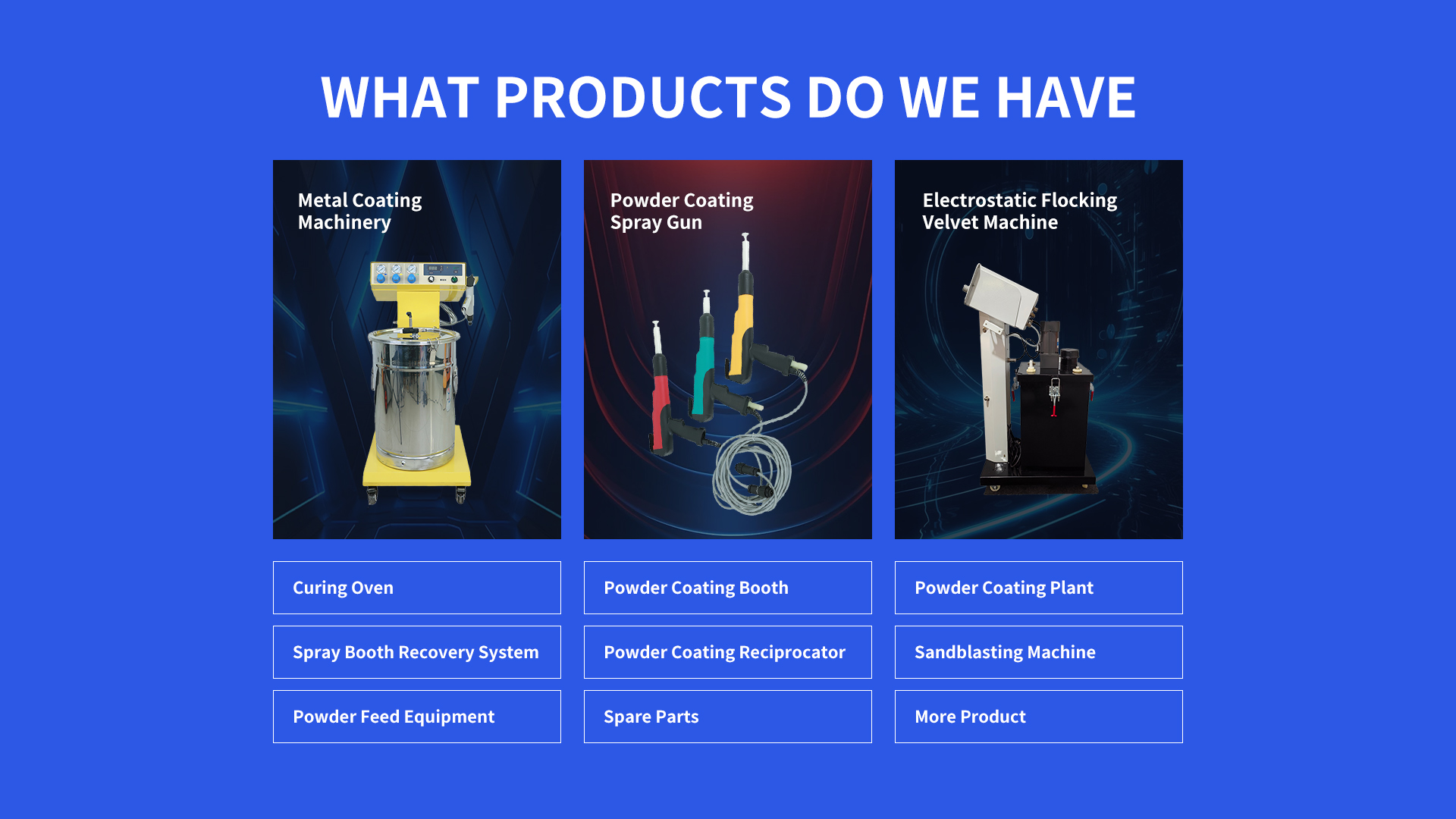

1. Industrial Powder Coating Machine Overview and Components

Industrial Powder Coating Machines are advanced systems designed for high-volume, precision coating applications. Key components include spray guns, electrostatic generators, powder hoppers, conveyor systems, and curing ovens. Constructed from stainless steel or corrosion-resistant alloys, these machines ensure durability and efficiency in demanding industrial environments. Automated models often integrate robotic arms and IoT controls for seamless operation.

2. Applications of Industrial Powder Coating Machines

These machines are essential in automotive manufacturing, aerospace component coating, appliance production, and heavy machinery industries. They provide uniform, corrosion-resistant finishes for parts such as engine blocks, aircraft components, and industrial tools, meeting strict quality and durability standards.

3. Industrial Powder Coating Machine Pricing

Prices range from 50,000forsemi−automaticsystems∗∗to∗∗over1 million for fully automated lines. Mid-range models (200,000–500,000) offer features like powder recovery and adjustable voltage controls. Customizations such as AI-driven robotics or multi-stage curing increase costs.

4. Proper Use of Industrial Powder Coating Machines

Ground equipment and workpieces to prevent electrostatic discharge.

Calibrate spray guns for optimal powder flow (20–50 grams per minute).

Maintain 8–12 inch spray distance for even coverage.

Monitor curing oven temperatures (300°F–450°F) based on material specifications.

Clean nozzles and filters daily to ensure consistent performance.

5. How to Choose Industrial Powder Coating Machines

Production Volume: Automated systems suit high-output factories; semi-automatic models fit medium-scale operations.

Material Compatibility: Verify compatibility with epoxy, polyester, or thermoplastic powders.

Energy Efficiency: Opt for systems with heat recovery and insulated ovens.

Certifications: Ensure compliance with OSHA, ISO, and environmental regulations.

6. Safety Precautions for Industrial Powder Coating Machines

Operators must wear respirators, anti-static suits, and goggles.

Install explosion-proof equipment in areas with flammable powders.

Regularly inspect electrical systems and ventilation.

Train staff on emergency protocols for fire or equipment failure.

7. Design Advantages of Industrial Powder Coating Machines

Modern designs prioritize sustainability and productivity. Closed-loop powder recovery systemsrecycle up to 95% of unused material, minimizing waste. Energy-efficient curing zones and IoT-enabled diagnostics reduce operational costs by 20–30%. Modular setups allow scalability as production needs evolve.

8. Industrial Powder Coating Machine Q&A

Q1: How do industrial powder coating machines improve efficiency?

A: Automated systems reduce overspray by 40–60%, ensuring precise material use and faster production cycles.

Q2: Can these machines handle high-temperature curing?

A: Yes, heat-resistant models support curing up to 500°F for specialized coatings.

Q3: What industries rely most on industrial powder coating machines?

A: Automotive, aerospace, and construction sectors depend on them for high-performance, durable finishes.

Q4: Are industrial powder coating machines eco-friendly?

A: Yes, zero VOC emissions and high powder recycling rates align with sustainability goals.

Q5: How to maintain industrial powder coating equipment?

A: Clean components daily, replace filters quarterly, and schedule annual electrical inspections.

This guide offers critical insights into industrial powder coating machines, empowering businesses to enhance productivity, safety, and sustainability in large-scale coating operations.

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com